Free Sample Laser Cutting Stainless Steel Sheet Metal Fabrication

Service/OEM Laser Marking Logo Service

What is sheet metal bending?

CNC bending (combined with laser cutting) is one of the most

underrated processes in small to medium batch sheet metal

production, especially when the quantities (hundreds to thousands

or more per batch) are not high enough to justify the high cost and

difficulty of manufacturing Situations where maintenance of

stamping tools, or where production speed and flexibility are

important. The ability to produce parts in a variety of geometries

without tools, fast lead times, high levels of repeatability and

automation mean sheet metal bending is a key tool for product

developers, engineers and business owners looking to manufacture

metal parts

Even at the design stage, understanding the bending possibilities

of sheet metal is important because it is a tool that gives

engineers great flexibility to create a variety of shapes and, in

many cases, allows parts to be created from a single piece of

material , rather than joining multiple parts together by hardware

or welding, reducing overall cost and increasing strength,

simplifying assembly and requiring few tools

OEM CNC Metal Bending

TUV CNC Metal Bending part

laser cutting stainless steel sheet

advantage

Manufacturing Speed - Once designed and programmed, sheet metal parts can be produced

very quickly, enabling a large number of components to be produced

in produced in a relatively short period of time

Accuracy - Sheet metal parts can be very precise, with laser cut holes within

±0.1mm, if adequate design considerations are given. There is a

high level of repeatability here, as programmed laser cutters and

CNC press brakes with appropriate software and equipment are

produced with low variability

Less post-processing – Welding often requires multiple passes to complete a part; heat

typically deforms the material and requires straightening, and

time-consuming and labor-intensive grinding and polishing are

required to remove weld spatter. Bending doesn't have these

problems - the part is ready to go straight from production

Lighter weight - Due to the complexity of the available bending, stiffness and

strength can be achieved while using relatively less material,

thereby also reducing part weight. It benefits every step of the

supply chain, including shipping

Low cost and virtually no tools - Thanks to advances in technology, CNC cutting and bending reduces

the manual labor required to produce parts, sheet metal bending

processes benefit from this technology more than most, using

CNC-controlled tools, parts can be made by skilled workers Lower

workers produce in less time, all resulting in lower final costs

Laser cutting and sheet metal bending processes generally do not

require specialized tools, as most manufacturers carry a range of

general-purpose tools that can produce most standard bends. This

means no tooling investment and significantly reduced lead times,

as there is no need to wait for complex tooling to be produced,

tested or adjusted

High-precision process is ideal when high precision is required

Can be mass-produced in a short time

Low production cost and low mold cost

laser cutting stainless steel sheet

Suitable for high or small batch production

Multiple custom shapes can be created through a range of bending

processes

Standard punches and dies available, including V and U shapes

Product Description

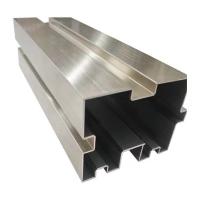

| name | Laser Cut Metal Bending Services |

| Material | Stainless steel, aluminum, copper, brass, carbon steel, etc. |

| process | Cutting, bending, punching, punching, welding, drilling |

| Serve | Customized ODM/OEM |

| color | natural color / color |

| surface treatment | Spray paintingpowder coatingelectroplatingpolishing, etc. |

Product Description