OEM Metal Custom High Quality Laser Cutting Service Aluminum

Stainless Steel Bending Sheet Metal Parts

Why use laser cutting

Lasers have many uses. One way they are used is to cut sheet metal.

On mild steel, stainless steel and aluminum sheets, the laser

cutting process has high precision, excellent cutting quality, very

small kerf width, small heat affected zone, and can cut very

complex shapes and small holes

Advantages of Laser Cutting Metal

Save material. Can be machined at any curved profile with very

small distances between components, providing high sheet fill rates

compared to other traditional sheet cutting methods

It takes a little time to prepare the file, and the probability of

program error is very low

The workpiece is not affected by mechanical loads during cutting,

avoiding deformation

No post-processing of cut edges required - clean cut edges

perpendicular to the plane of the sheet; no line edges

High size and repeatable accuracy

Another advantage of laser cutting is that it can engrave the

product - where the joints of the welded product are joined, small

holes are drilled in thick metal

Laser cutting technology can quickly cut even a small number of

low-tech sheet metal parts

high productivity

How is metal formed and bent during manufacturing?

When you're looking for a more economical way to achieve 2D and 3D

shapes, CNC or press brake metal bending is the most efficient way

to get the job done. Metal bending and forming involves bending in

metal as needed using specialized machines to create the shape you

are looking for. This method is used to create custom shapes for

various industries

In metal bending and forming, having the skills and equipment to

create precise bends over and over is paramount. If the bend is not

accurate, the part may fail or not work with existing parts

Bending machine sheet metal bending

What is Bending Machine Metal Bending? Sheet metal bending refers

to the type of machine you use to bend metal, in this case a press

brake. Press brakes allow you to bend metal into custom shapes with

high precision, making it a very popular machine for applications

that require high precision

The right press brake also allows you to bend large pieces of metal

or multiple small pieces in less time, increasing speed and

increasing production cycle times

Many manufacturing companies rely on sheet metal forming when

working with aluminum, stainless and carbon steel. What makes this

method so attractive compared to other methods? Here are some of

the benefits of sheet metal bending with a press brake:

Easy to implement in small and large batch runs

Minimize tool requirements

mass to form smaller components

The effectiveness of ductile materials

Special punches and dies, including V and U shapes

We can assist you with all your sheet metal fabrication needs, from

design to every stage of the production process

Our in-house metal product fabrication services include design and

engineering, cutting, metal stamping, metal forming, fabrication,

powder coating and final assembly; all projects are managed by our

knowledgeable team

Product Description

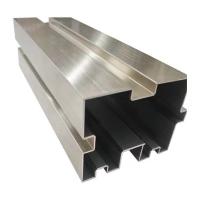

| product name | sheet metal |

| Specification | Made according to your drawings |

| Serve | OEM/ODM |

| processing | Laser cutting/cutting/punching/bending/welding/coating/other |

| Package | Wooden case/pallet/carton/according to customer requirements |

| surface treatment | Electroplating, anodizing, polishing, wire drawing, etc. |

Product Image